Simcenter STAR-CCM+ 2410, the latest version, brings several significant updates to the field of engineering simulation, aimed at improving simulation accuracy, accelerating computation speed, and optimizing the user experience.

These new features include battery aging prediction, VOF simulation acceleration, SPH surface tension modeling, GPU acceleration support for the Windows platform, multi-body instancing, dynamic slicing and clipping, among others. With these improvements, engineers can more efficiently simulate and analyze complex physical phenomena, aiding in product development and optimization.

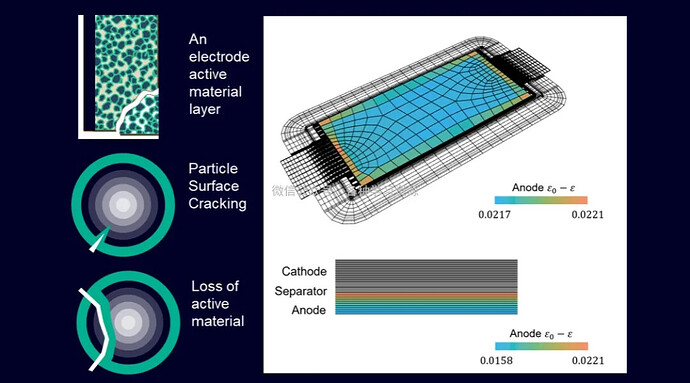

1. Improvements in Battery Cell Aging Prediction

In the field of battery simulation, Simcenter STAR-CCM+ 2410 introduces two sub-grid particle aging models: “active material loss” and “surface crack growth.”

These models simulate local aging effects caused by mechanical stress, such as crack formation during lithium cycling. These models enable users to more accurately predict changes in battery capacity and internal resistance, thereby improving the accuracy of battery life and reliability predictions.

2. Dynamic Implicit Multistep Method to Accelerate VOF Simulation

For Volume of Fluid (VOF) simulations, Simcenter STAR-CCM+ 2410 introduces a dynamic implicit multistep method.

This method allows for larger constant time steps while maintaining simulation stability through dynamic sub-steps. Compared to traditional methods, this improvement can increase simulation speed by nearly two orders of magnitude, significantly reducing simulation time.

3. SPH Surface Tension Model

In Smoothed Particle Hydrodynamics (SPH) simulations, Simcenter STAR-CCM+ 2410 adds a surface tension model.

This model allows users to simulate liquid behavior on hydrophilic or hydrophobic surfaces, improving the simulation accuracy of liquid-solid interactions in applications such as lubrication.

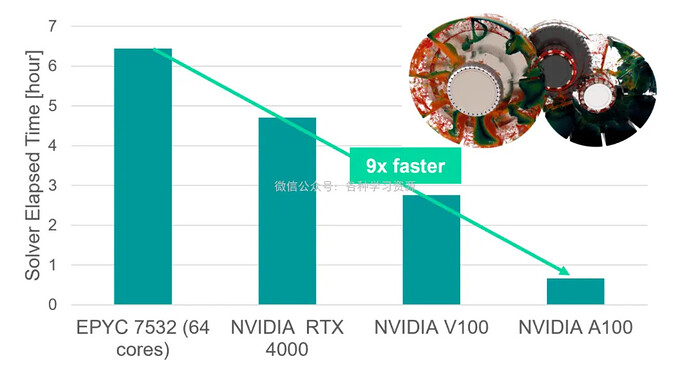

4. GPU Acceleration Support for Windows Platform

Simcenter STAR-CCM+ 2410 extends GPU-based native physical solvers to the Windows platform.

Users can now take advantage of GPU acceleration on Windows workstations, significantly reducing simulation times.

5. Multi-Body Instancing Feature

In CAD processing, Simcenter STAR-CCM+ 2410 introduces a multi-body instancing feature.

Users can create instances of a part by patterning or rotating features, with modifications to one instance synchronized across all instances. This feature reduces geometry preparation time and memory usage, improving the efficiency of handling complex CAD assemblies.

6. Fast and Easy Modeling of Multi-Stage Solid Stress and Fluid-Structure Interaction

Simcenter STAR-CCM+ 2410 allows users to automate multi-stage solid stress and fluid-structure interaction (FSI) case setups by leveraging stage-specific physics and simulation operations.

Users can combine specific loads and boundary conditions into different stages, simplifying the setup process and improving modeling efficiency.

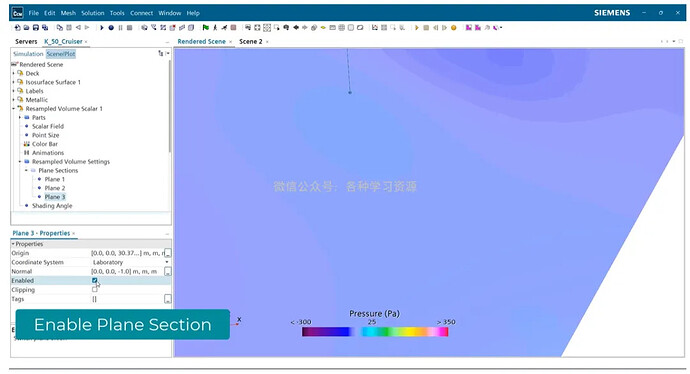

7. Dynamic Slicing and Clipping Feature

For volume data analysis, Simcenter STAR-CCM+ 2410 provides dynamic slicing and clipping features.

Users can dynamically slice and clip re-sampled volume data to hide unnecessary elements and highlight areas of interest, making it easier to understand flow behaviors.

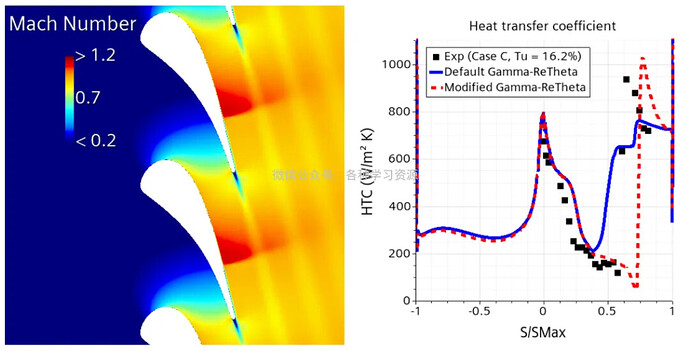

8. User-Defined Gamma and Gamma-ReTheta Model Source Terms

For turbulence transition modeling, Simcenter STAR-CCM+ 2410 introduces user-defined source terms for the Gamma and Gamma-ReTheta models.

Users can adjust transition behavior for specific industrial applications, improving simulation accuracy and meeting the needs of different scenarios.

9. Improved Spray Collision Detection Method

In spray modeling, Simcenter STAR-CCM+ 2410 employs a new collision detection method that uses cell clusters to identify collision pairs, reducing unrealistic spray shapes caused by mesh dependencies and improving the accuracy of spray shape and droplet size predictions.

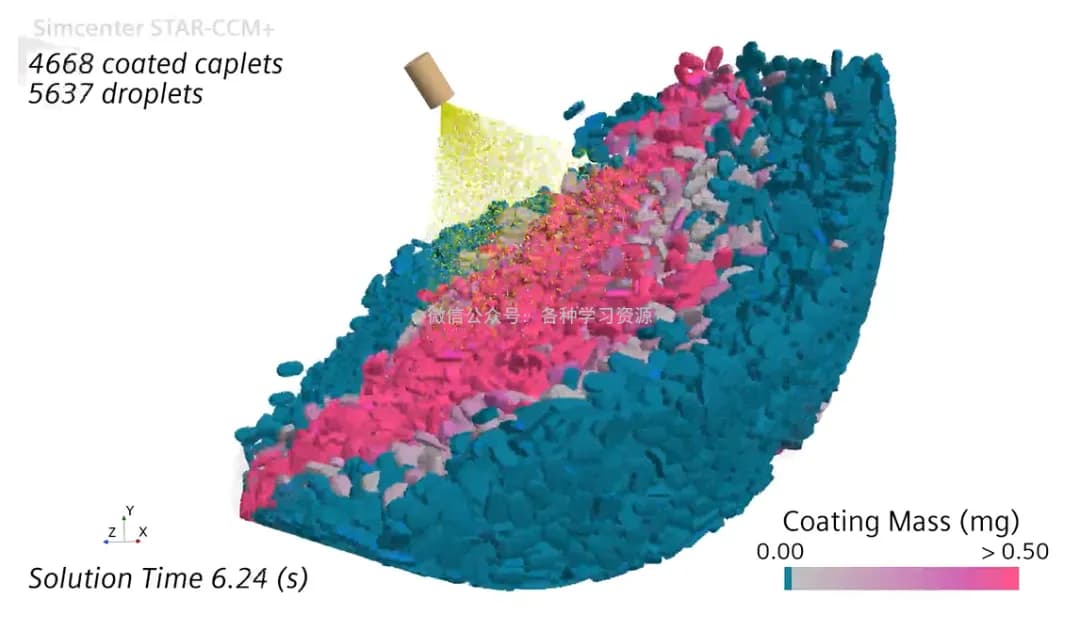

10. Absorption Model for Liquid-Solid Interactions

In pharmaceutical and chemical industries, Simcenter STAR-CCM+ 2410 introduces an absorption model for liquid-solid interactions.

This model allows simulation of mass transfer between droplets and solid particles, realistically replicating wetting behaviors in processes such as tablet coating, enhancing simulation realism.

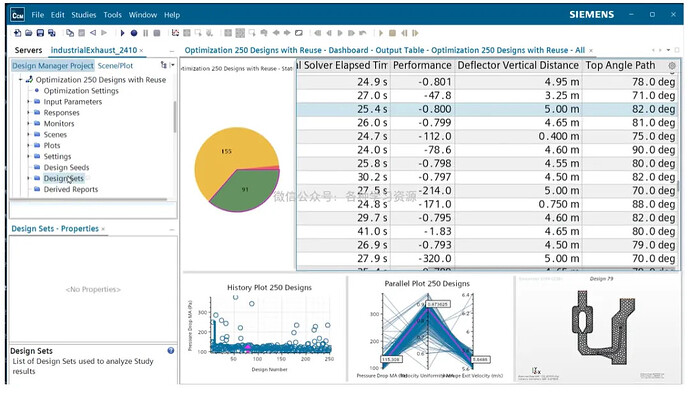

11. Derived Report Function in Design Exploration

In Design Exploration, Simcenter STAR-CCM+ 2410 allows users to perform column operations in output tables and calculate metrics such as averages, totals, or standard deviations using expressions.

This feature enables users to derive reports from study metrics, gaining deeper insights into results and assisting in design optimization decisions.

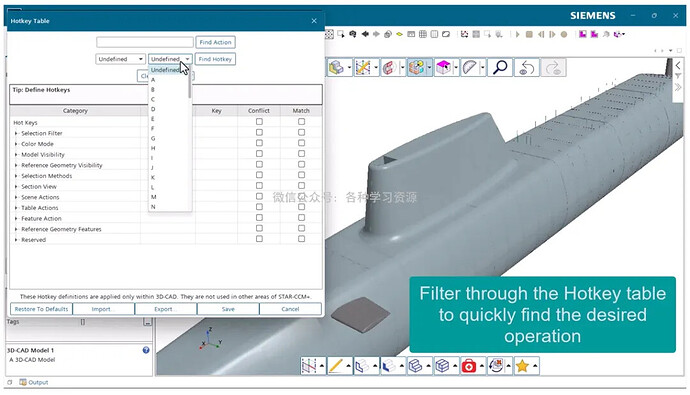

12. Customizable Shortcut Keys

In the 3D-CAD interface, Simcenter STAR-CCM+ 2410 allows users to define custom shortcut keys for any operation.

Users can quickly access frequently used actions, improving workflow efficiency, and support for importing and exporting shortcut sets facilitates team collaboration.