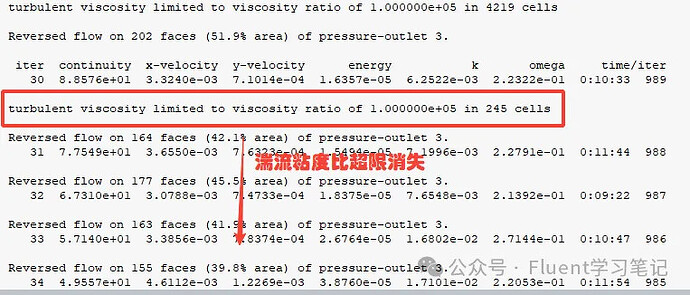

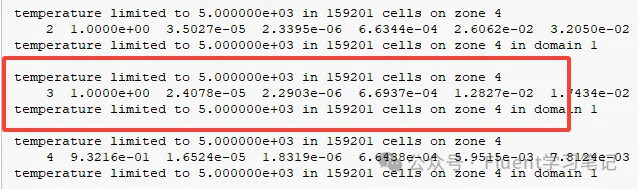

The convergence behavior in Fluent is often similar, but divergence situations can vary widely. Sometimes, rather than getting caught up in how to achieve convergence, it’s more useful to understand what to do if divergence occurs.

In the following sections, we will discuss several scenarios that often arise during calculations. Many times, these situations do not indicate true divergence but are common issues encountered during the computation process. Many students are unsure of how to address these problems or whether they can continue the calculation, and if they do, whether the results will be accurate. This article will provide a detailed overview to help clarify these concerns.

Problem 1: Outlet Backflow

- 1 出口回流介绍

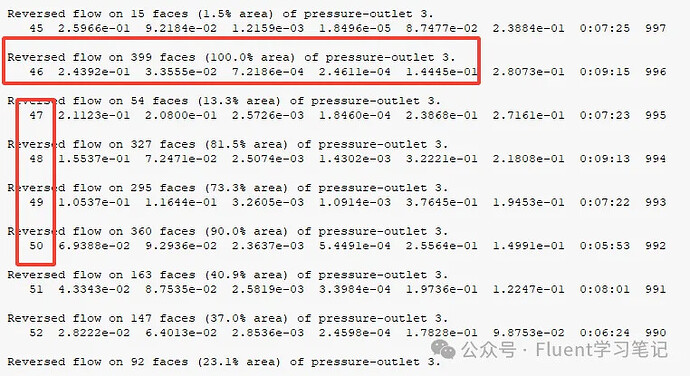

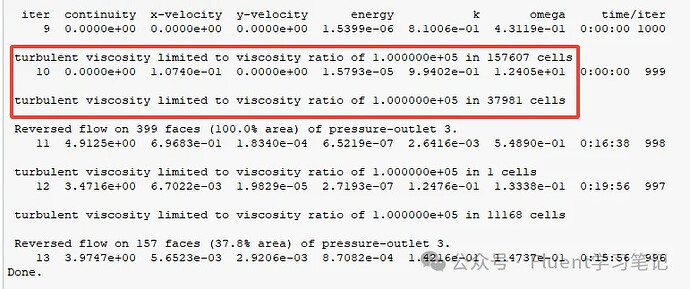

Reversed flow on 16 faces (4.1% area) of pressure-outlet 3

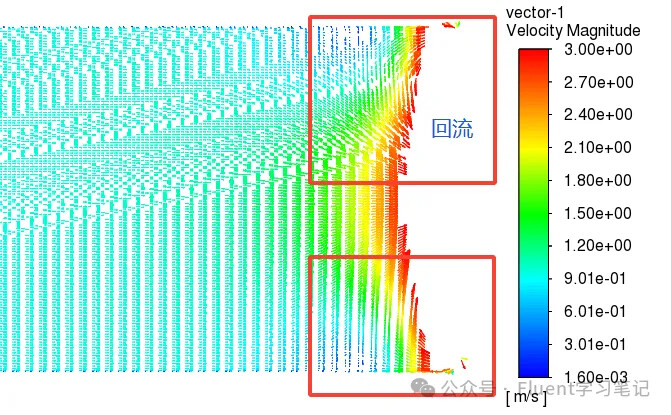

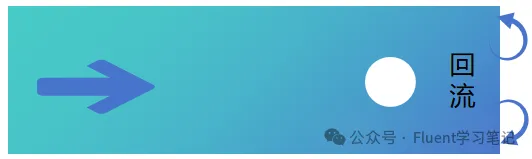

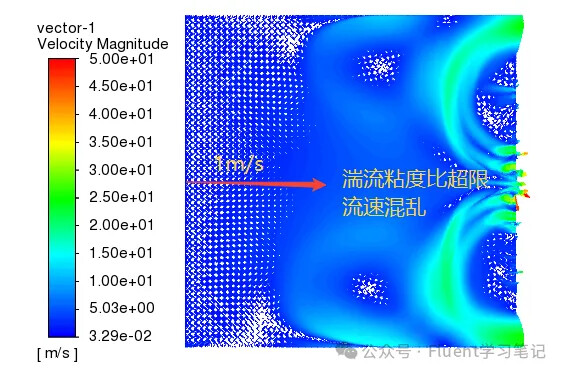

Outlet backflow is a common occurrence in simulations. It refers to a situation where fluid that is supposed to exit the model through the outlet instead flows back into the computational domain. This is clearly inconsistent with the physical reality of the scenario.

The occurrence of outlet backflow can generally be categorized into three types:

- Initial Backflow During Calculation:

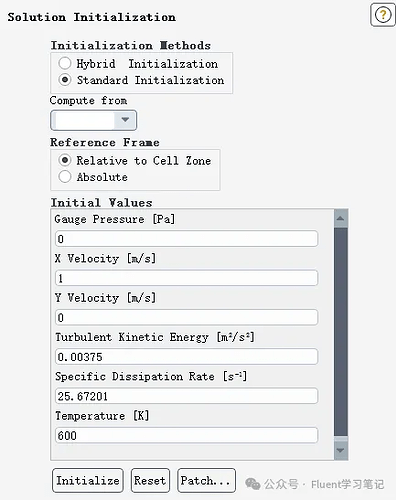

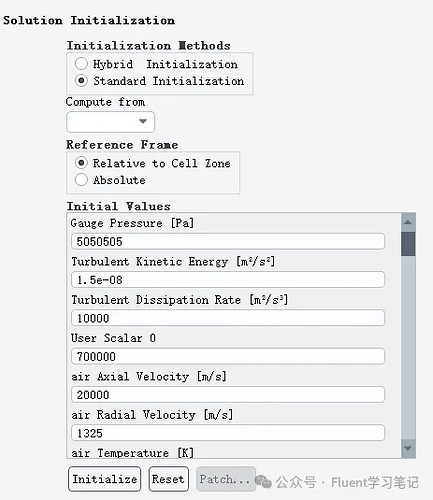

- This situation arises at the beginning of the simulation when the flow conditions are still settling. It may occur if the initial conditions are not set appropriately, leading to instability. To address this, ensure that initial conditions are physically realistic and closer to the expected flow state.

- Unreasonable Physical Model:

- If the physical model or boundary conditions do not accurately represent the real-world scenario, backflow may occur. This can happen if the geometry is not modeled correctly, or if the flow rates and pressures do not match the physical reality. Reviewing and revising the physical model and boundary conditions can help resolve this issue.

- Divergence in Calculations:

- Divergence indicates that the numerical solution is unstable, often resulting in erratic flow behavior and backflow. This can happen due to inadequate mesh quality, incorrect solver settings, or inappropriate relaxation factors. To mitigate divergence, consider refining the mesh, adjusting solver settings, and ensuring that boundary conditions are correctly defined.

-

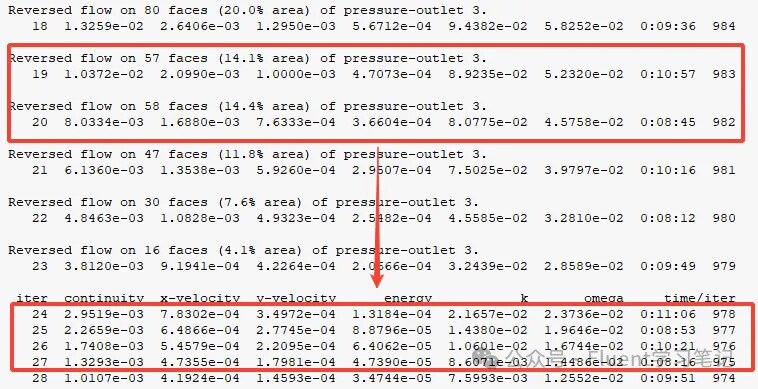

2. Initial Backflow During Calculation

When starting a calculation and only running a few dozen steps, the occurrence of backflow is normal. As long as you continue the simulation, this phenomenon will eventually disappear.

-

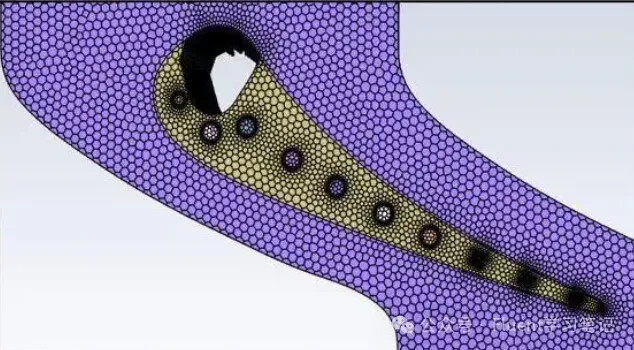

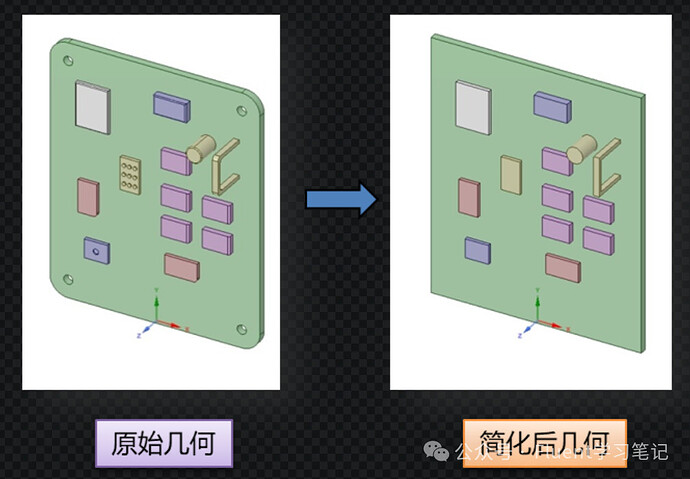

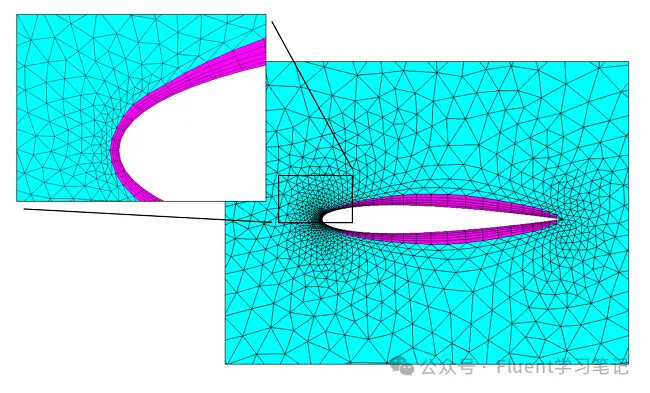

3. Unreasonable Physical Model

If there are issues with the modeling, this situation can also arise. Even if the simulation continues running, the backflow phenomenon may not disappear, typically due to problems with the physical model. For instance, if the tail of the Kármán vortex street is too short and vortices are still present at the outlet, then backflow at the outlet is a normal occurrence.

To resolve this issue, adjustments to the physical model are necessary, such as increasing the length of the wake region.

-

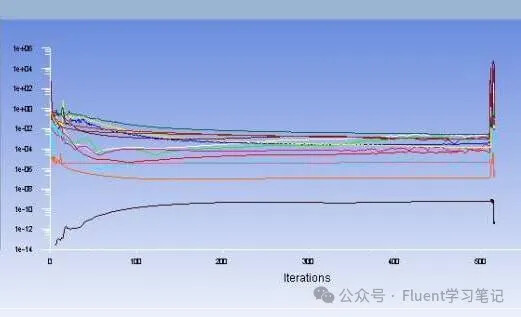

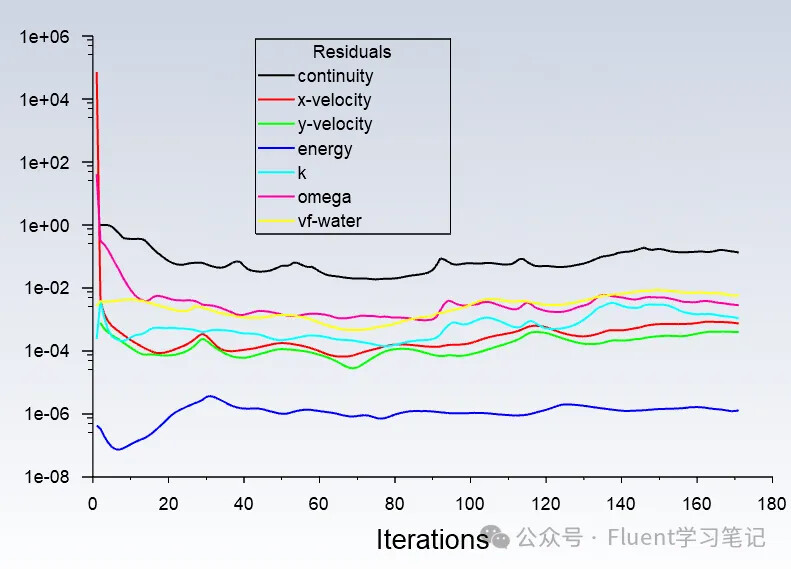

4. Divergence in Calculations

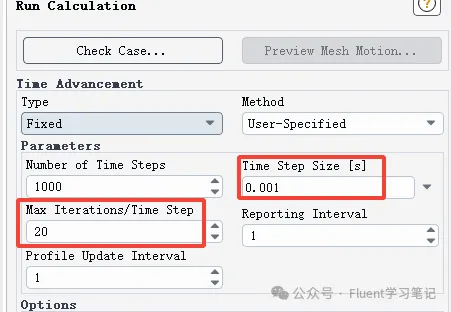

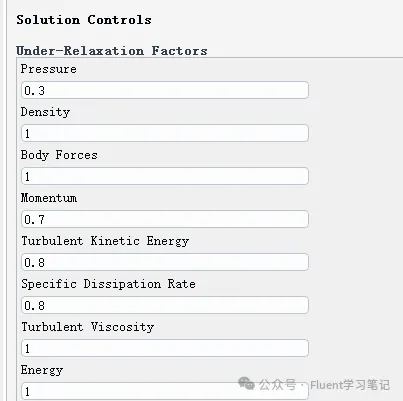

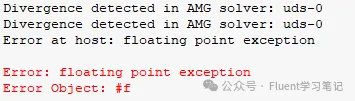

The last situation is indeed divergence, where the velocity fluctuations in the flow field during the calculation are too significant. This can lead to numerical instability and prevent convergence.

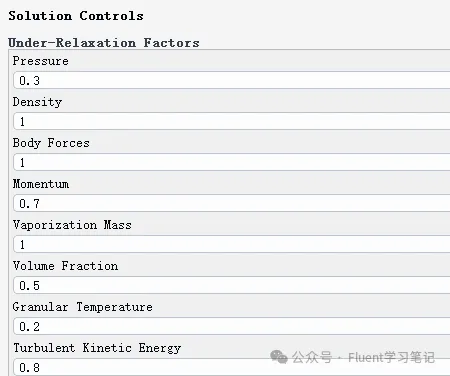

At this point, the only option is to check the settings individually. The most common causes of divergence include:

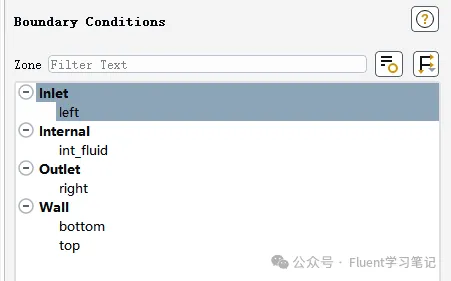

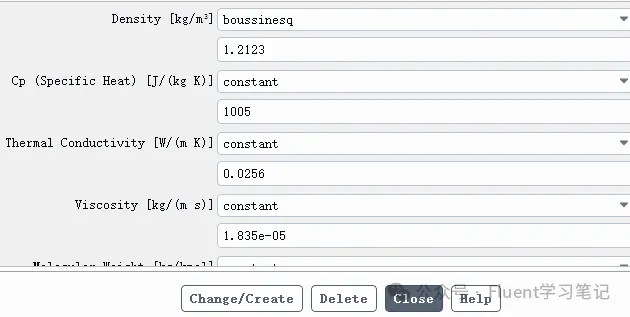

- Inappropriate Boundary Conditions: Ensure that all boundary conditions are defined correctly and realistically to match the physical scenario.

- Poor Mesh Quality: Examine the mesh for issues such as high skewness or low quality in critical areas. Improving the mesh can enhance numerical stability.

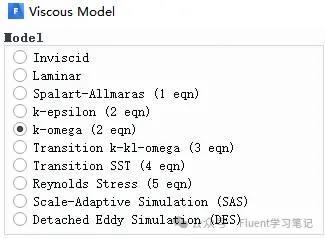

- Inadequate Selection of Mathematical Models: Verify that the chosen mathematical models (e.g., turbulence models) are suitable for the flow characteristics and conditions being simulated.