0. Abstract

Biological 3D printing is a technology that uses 3D printing methods to create living tissues and organs by printing with biological materials. It has several different techniques, which are based on different principles and materials. Below, I will give you a brief introduction to these various printing processes.

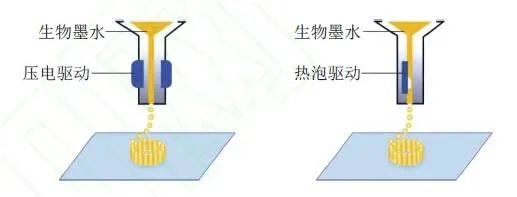

1. Inkjet-based 3D Bioprinting

Inkjet-based 3D bioprinting is one of the earliest technologies used in biological 3D printing. The principle is similar to traditional 2D inkjet printing. Using piezoelectric or thermal-driven printheads, bio-ink (a mixture of hydrogel and cells) is divided into a series of micro-droplets. These droplets are printed layer by layer to form a 3D structure containing cells. The key challenge in this process is ensuring that the micro-droplets bond and fuse together properly.

This method is relatively low-cost, as commercial inkjet printers can be modified for 3D bioprinting. Multiple printheads can be used on an inkjet printer to print different types of cells simultaneously, speeding up the printing process. However, due to the low driving pressure of the printhead, it cannot print high-viscosity materials or highly concentrated cell mixtures. Additionally, the printing process may cause mechanical or thermal damage to the cells, which limits the widespread use of inkjet bioprinting.

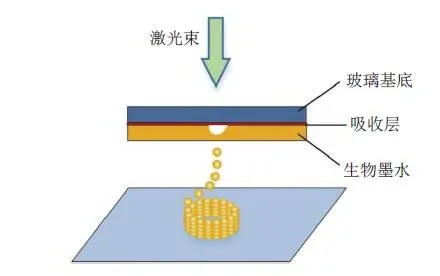

2. Laser Direct Writing 3D Bioprinting

Laser Direct Writing (LDW) is another method of 3D bioprinting that uses droplets of material as the basic unit of formation. Laser energy is used to generate micro-bubbles in a laser-absorbing material, which avoids the direct contact between cells and high-energy lasers. First, a layer of laser-absorbing material is applied to a glass substrate, and bio-ink is evenly spread on top. During printing, a laser beam passes through the substrate, creating bubbles in the absorbing material. These bubbles expand, pushing the bio-ink and cells away from the substrate and onto the forming platform.

Compared to inkjet printing, LDW can avoid direct contact between the bio-ink and the handling equipment, thus minimizing mechanical damage to the cells. It can print materials with higher viscosities, and the range of usable materials is broader than inkjet printing. However, this technique is still primarily in the research stage. The high cost of LDW printers, along with immature processes and a lack of commercial devices, limits its use. Furthermore, coating bio-inks onto laser-absorbing material for each layer can be time-consuming.

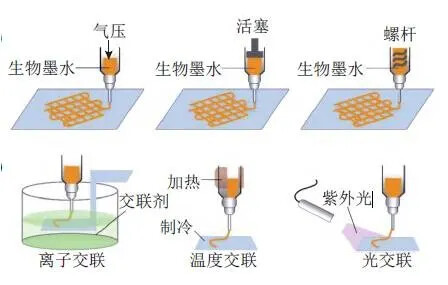

3. Extrusion-based 3D Bioprinting

Extrusion-based 3D bioprinting is one of the most widely used methods for bioprinting. It can print higher viscosity biological materials. The process uses either air pressure or mechanical-driven printheads to extrude bio-ink in a controlled manner. Microfibers are extruded from the printhead and deposited onto a forming platform to create a 2D structure. As the printhead or forming platform moves in the z-direction, the 2D structure builds up layer by layer to form a 3D structure.

In extrusion printing, continuous extrusion allows for uninterrupted fibers, rather than single micro-droplets, making it suitable for a wide range of materials and concentrations of cells. It can produce structures with better mechanical strength, making it ideal for printing tissues with required functional characteristics.

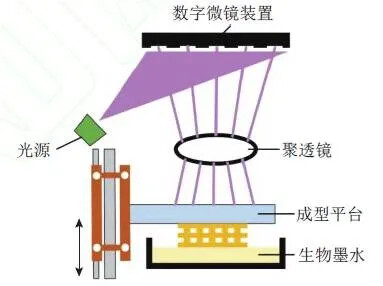

4. Photocuring-based 3D Bioprinting

Photocuring-based 3D bioprinting is similar to laser direct writing but uses light to selectively crosslink bio-inks, layer by layer, to form a 3D structure. Ultraviolet (UV) light is selectively projected onto the surface of bio-ink using a digital micromirror device (DMD), and the exposed area of the material begins to cure. The forming platform moves up and down, and the process repeats layer by layer to create a complete 3D structure.

This technique is efficient because the digital light projector cures the entire surface of the bio-ink in one go, resulting in consistent printing times regardless of the complexity of the single-layer structure. The printing accuracy is high, and the system is relatively simple, with only vertical movement needed for the platform. However, the use of UV light and curing agents can cause cell damage, which is a significant limitation.