1. Adjusting the Mesh Size in Abaqus

- Simple Explanation: Experiment to find the most suitable mesh density.

- Specific Operation: A reasonable mesh size is typically: for cross-sections, the mesh size should be 1/6 to 1/12 of the component’s width and height; the aspect ratio should be controlled between 1 and 2. In the depth direction, the length should be 0.6 to 2 times that of the cross-section mesh. Aim for the mesh to be as cubic as possible, and avoid excessive length ratios in any direction, with the depth usually being the longest.

- Evaluation: This method is highly recommended, but it can be time-consuming and computationally intensive. During the initial stages of batch modeling, different mesh configurations can be tested on typical components to determine the optimal density.

- Operability: ★★★

- Accuracy: ★★★★★

2. Changing the Tolerance

- Simple Explanation: Increase the allowable error in iterative calculations.

- Specific Operation: See below for details.

- Evaluation: This method is very effective but may introduce some error; the curves after adjusting the tolerance are usually not smooth and tend to be steeper. This approach is typically used for simulating elastic-plastic segments, where significant deformation can make convergence difficult.

- Operability: ★★★★★

- Accuracy: ★★★

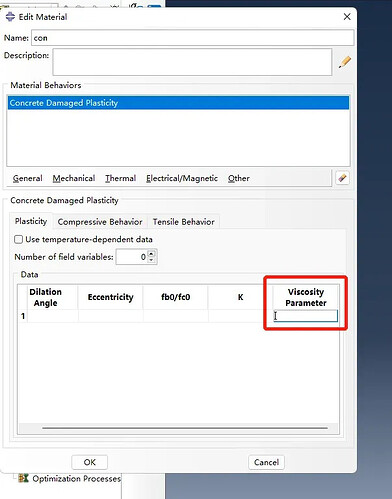

3. Modifying Viscosity Coefficient (Concrete CDP Model)

- Simple Explanation: Increase the viscosity coefficient, originally set to 0, adjusted between 1e-5 and 1e-7.

- Specific Operation: For components with concrete using the CDP (Concrete Damage Plasticity) model, a higher viscosity coefficient improves convergence, but the data may be inaccurate.

- Evaluation: Relatively easy to implement, but it may introduce some error; peak values are generally lower than actual values.

- Operability: ★★★★

- Accuracy: ★★★

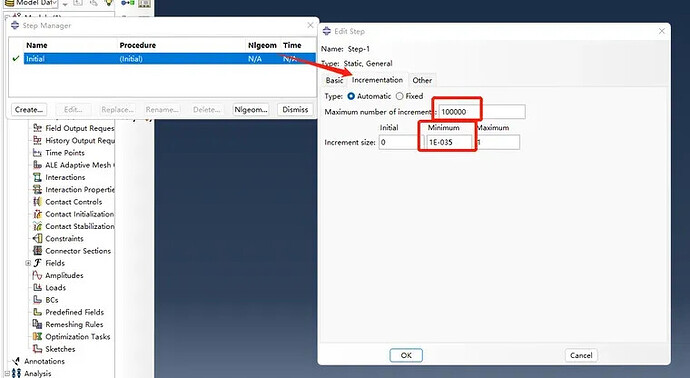

4. Adjusting Minimum Steps and Maximum Iterations

- Simple Explanation: During iterative calculations, if the error exceeds the required threshold, the system continues to iterate until the error is less than the threshold. If the maximum number of iterations is exceeded, the calculation cannot proceed, so the iteration steps should be large. For iteration step size, if the error is significant, the software will proceed cautiously, resulting in very small steps. For example, if you set it to 1e-5, the model may still calculate with a 1e-6 step size, but the system will directly terminate the computation. Therefore, setting the minimum step size smaller may facilitate convergence.

- Specific Operation: Generally adjusted to a minimum of 1e-35.

- Evaluation: This method is somewhat effective but can lead to large ODB files, consuming significant computational resources.

- Operability: ★★★★

- Accuracy: ★★★★

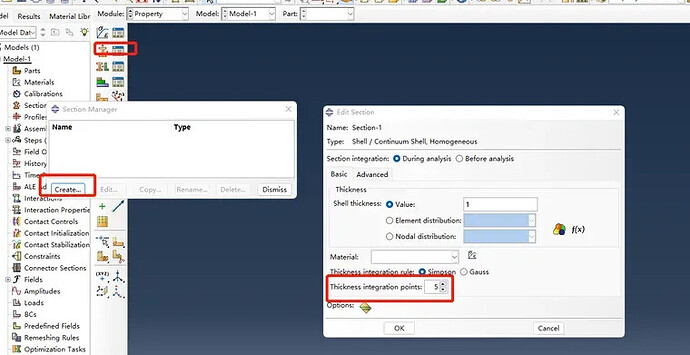

5. Adjusting Thickness Integration Points (Shells)

- Simple Explanation: When integrating the thickness of a shell, having 3 integration points indicates a cubic simulation, while 5 points indicate a fifth-degree polynomial simulation. Higher-degree polynomials are more accurate but harder to converge.

- Specific Operation: Typically, a fifth-degree polynomial is used; to ensure smoother simulations, a third-degree polynomial can be employed, slightly reducing computational accuracy.

- Evaluation: This is applicable for shells but not particularly significant.

- Operability: ★★★

- Accuracy: ★★★

6. Summary

In writing papers, Abaqus is used at different stages, including pre-experiment simulations, simulations of test components, parameter analysis, and mechanism analysis.

- Pre-Experiment Simulations: Since the simulated values are only rough estimates of component capacity, deviations within 20% are acceptable. All methods can be applied to obtain the curve.

- Test Component Simulations: Accuracy is paramount; avoid methods that compromise precision, keep viscosity coefficients within a narrow range, and optimize mesh configurations to capture as many plastic segments as possible.

- Mechanism Analysis: As the entire process needs to be analyzed, slight adjustments in tolerance and viscosity may be used to ensure a sufficiently long plastic segment for analysis. However, tolerance and viscosity should not be excessively adjusted, as it can result in steep stress plots that hinder effective analysis.

- Parameter Analysis: This is more complex, typically ensuring accuracy in the early stages and computational feasibility later on.